Solutions for the whole metals value chain

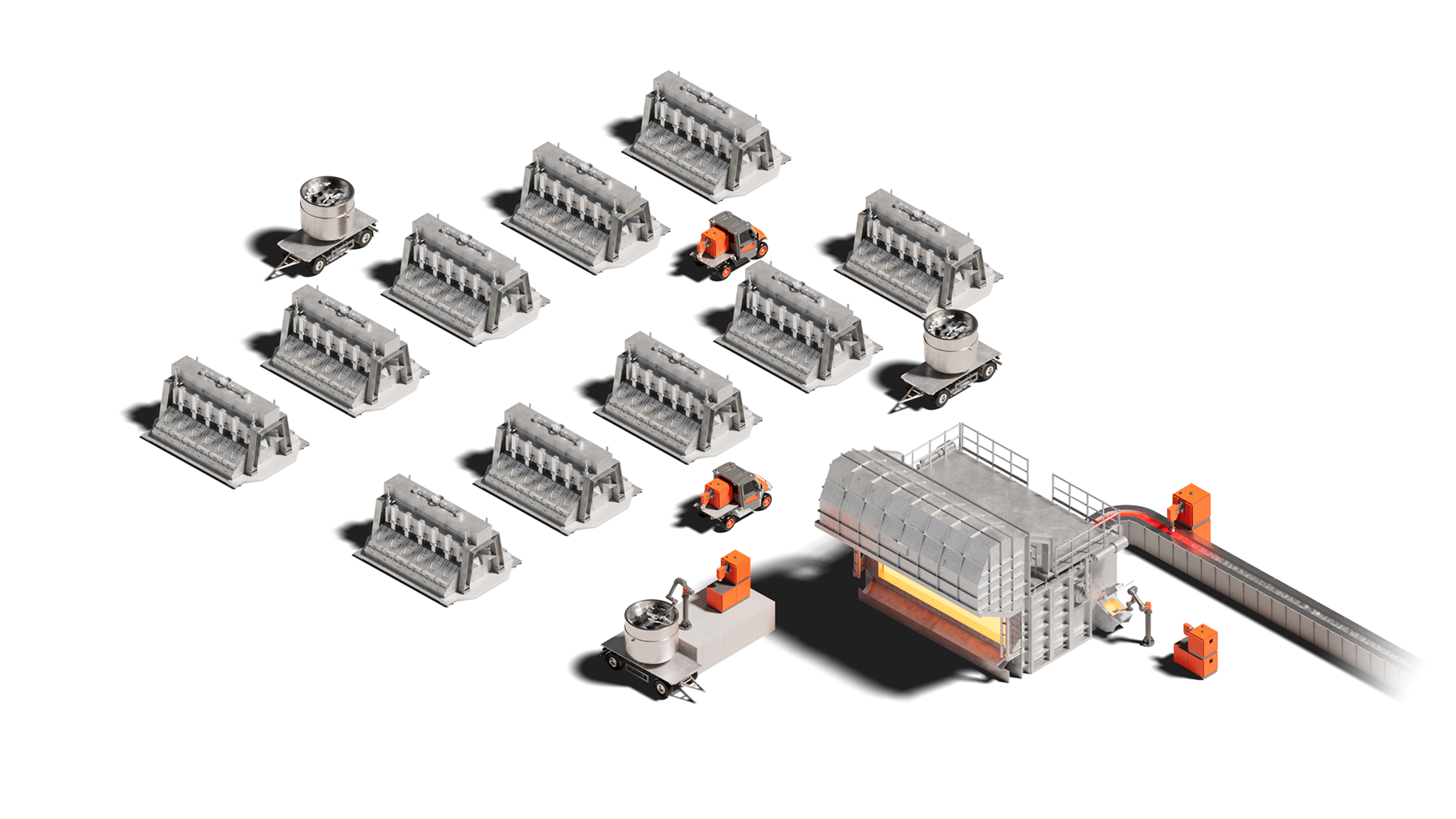

DTE’s solutions can be implemented at every process point where molten aluminum is handled: in potrooms; in primary smelters; in casting operations in transfer crucibles, furnaces and launders; in scrap recycling plants, both in remelting and casting furnaces and launders; and for end-user manufacturers who cast parts or products from molten aluminum.

Potroom

Crucible

Furnace

Launder

DTE offers comprehensive services for potroom management, including optimization of tapping schedules, extending the operational lifetime of pots, reducing the risk of error through next-to-pot analysis, instant detection of sample contamination, and minimizing laboratory costs.

DTE provides fully automated analysis services, along with robotic extraction of metal, ensuring the correct routing of materials for the cast house, optimizing furnace charging, and facilitating aluminum alloy processing.

DTE specializes in optimizing furnace loading, increasing throughput, enhancing energy efficiency, minimizing scrap and rework, and prioritizing operator safety.

DTE's launder solutions encompass fully automated analysis, applicable for both primary metal and alloys, featuring stationary equipment providing a full chemical profile during casting and prioritizing operator safety throughout operations.

Want to know more?

Schedule a call with our expert team.